Locomotion

Week 1 • CMPSC 304 Robotic Agents

Press Space or → to advance

Today's Agenda

- What is actuation?

- Locomotion vs. manipulation

- Static vs. dynamic stability

- Degrees of Freedom (DoF)

- Wheel types and kinematics

Actuation: Making Robots Move

Two key types:

- Locomotion: Moving the robot itself

- Manipulation: Moving objects in the environment

The Duality of Movement

Both use the same principle:

- Motors exert forces on the environment

- Locomotion: Forces on ground/water/air → robot moves

- Manipulation: Forces on objects → objects move

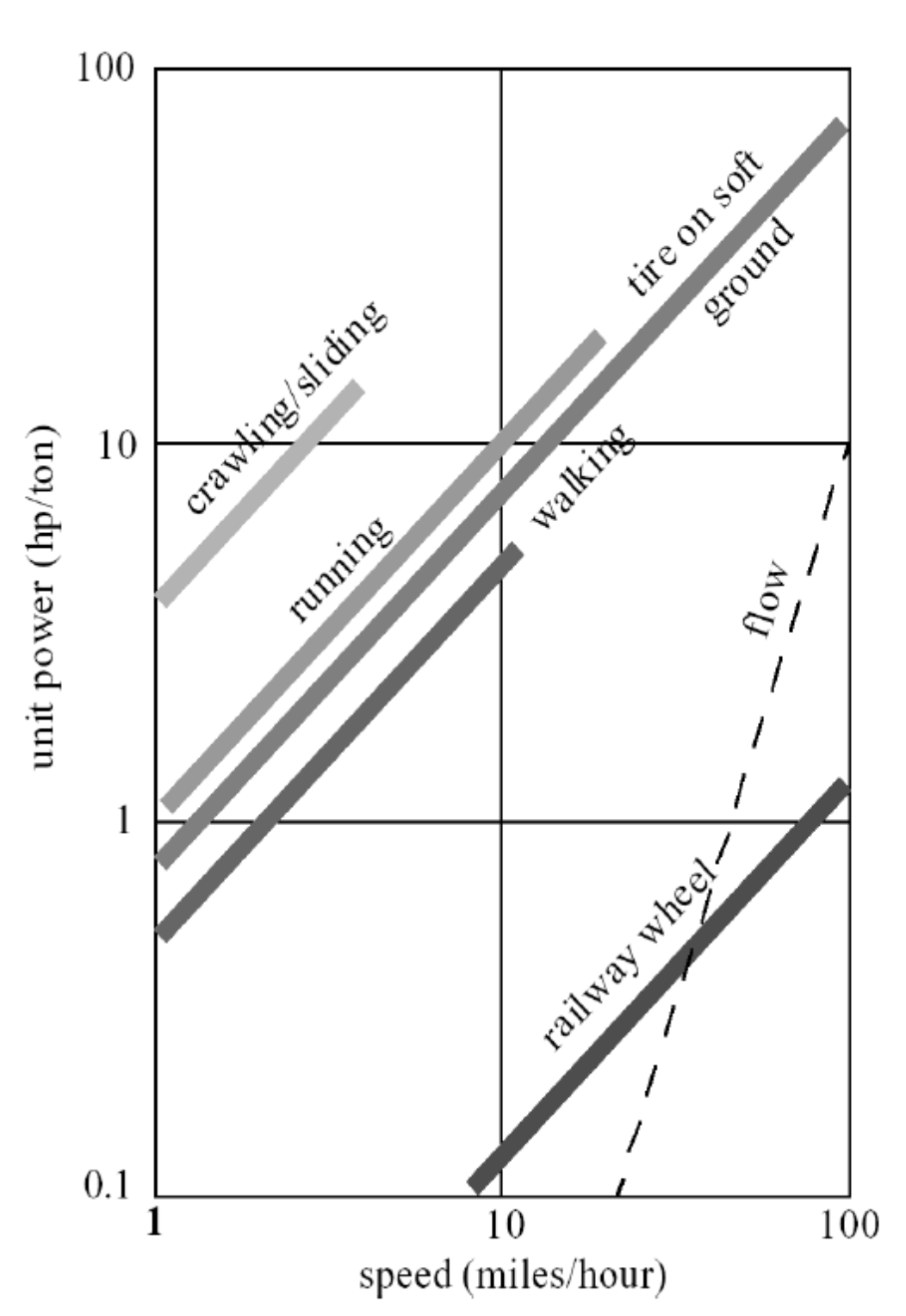

Locomotion Methods

Trade-offs: energy efficiency, terrain, speed, stability, cost

Energy Efficiency

Railway wheels ~10× more efficient than walking

But Wheels Have Limits

Great For:

- ✓ Roads

- ✓ Warehouses

- ✓ Flat floors

Poor For:

- ✗ Forests

- ✗ Mountains

- ✗ Rough terrain

This is why evolution never created wheeled animals

Stability Types

Static

Won't fall when not moving

- ✓ Stable at rest

- ✓ Slower movements

- ✓ Simpler control

Dynamic

Requires constant motion

- ✓ Faster, agile

- ✗ Complex control

- ✗ Always actuating

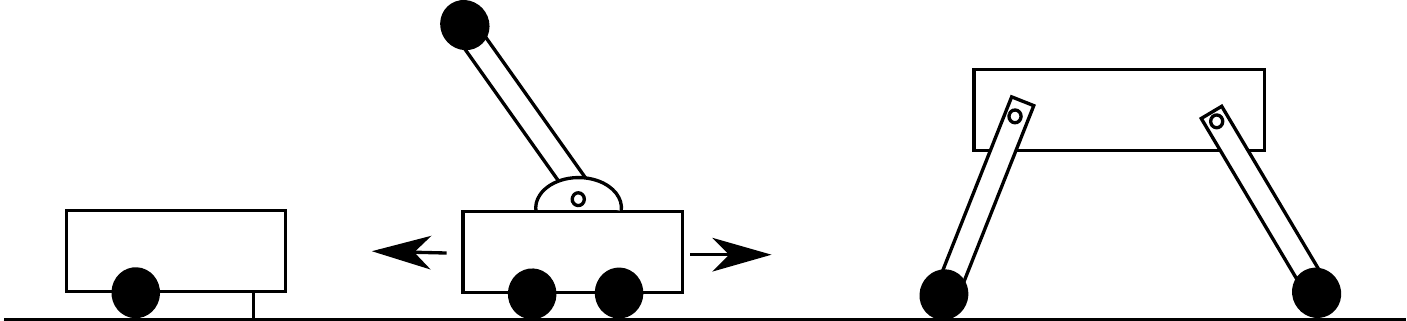

Stability Principle

- Left: Static (stable at rest)

- Middle: Dynamic (must keep moving)

- Right: Both modes possible

Real-World Examples

Six Legs

(Insects, hexapods)

- Statically stable walking

- Move 3 legs at a time

- Triangle always supports

Four Legs

(Dogs, quadruped robots)

- Walking = static

- Running = dynamic

- Switch between modes

Degrees of Freedom (DoF)

Two types to distinguish:

- Cartesian DoF: Positions/orientations in space

(Maximum 6 in 3D space) - Mechanical DoF: Number of actuated joints

(Depends on robot design)

Cartesian DoF (3D Space)

- Forward/back

- Left/right

- Up/down

- Pitch

- Yaw

- Roll

Wheel Types & DoF

Different wheel types enable different mobility

Standard Wheel (2 DoF)

Two degrees of freedom:

- Rotation around the wheel axle

- Rotation around ground contact point

Cannot move sideways (would require skidding)

Example: Bicycle wheel, car wheel

Caster Wheel (3 DoF)

Three degrees of freedom:

- Rotation around the wheel axle

- Rotation around ground contact

- Rotation around the caster axis

Example: Shopping cart, office chair

Swedish/Mecanum Wheel (3 DoF)

Three degrees of freedom:

- Rotation around main wheel axle

- Rotation around ground contact

- Rotation around roller axles

Result: True omnidirectional movement!

Kinematic Constraints

2-DoF wheels = Constrained movement

- A car can parallel park

- Requires multiple maneuvers

- Like a knight on a chessboard

Mobile Robot DoF on a Plane

A plane has 3 Cartesian DoF:

- X position (horizontal)

- Y position (vertical)

- Orientation (angle θ)

May need multiple moves to reach certain poses

Manipulator Arms: Mechanical DoF

On a plane (2D workspace):

- Up/down position

- Left/right position

- End-effector orientation

3 Cartesian DoF needed → Need ≥3 joints

Joint Types

Revolute (Rotary)

- Most common

- Rotates around an axis

- Example: Elbow, shoulder

Prismatic (Linear)

- Extends and contracts

- Slides along an axis

- Example: Telescope, piston

Design Trade-offs

Choosing kinematics involves balancing:

- Mechanical complexity

- Maneuverability

- Precision

- Cost

- Ease of control

• Differential: cheap, maneuverable, hard to drive straight

• Car: expensive, precise, hard to parallel park

Real Robot: Differential Drive

Configuration:

- Two powered wheels on shared axis

- One (or two) caster wheels for support

Advantages

- Very maneuverable

- Simple control

- Low cost

Challenge

- Hard to drive straight

- Needs matched motors

- Wheel wear issues

Key Takeaways

- Actuation enables locomotion and manipulation

- Stability can be static (at rest) or dynamic (requires motion)

- DoF describes what movements are possible

- Wheel type determines mobility constraints

- Design choices involve complex trade-offs

Before Next Class

Think about:

- What DoF does your robot need?

- Static or dynamic stability?

- Which wheel configuration?

- What trade-offs will you make?

Questions?

- Submit components list and team contract

- Finish Design

- Mechanical build

- Wiring and power

- Basic control

Readings: IAR Chapters 2 & 6