Motors and Arduino for Robotics

Week 2 • CMPSC 304 Robotic Agents

Press Space or → to advance

Today's Agenda

- Arduino Uno basics and power flow

- Digital vs. Analog signals

- Pulse Width Modulation (PWM)

- Battery voltage calculations

- Why we need motor drivers

- DC motors for Project 1

- Motor types overview

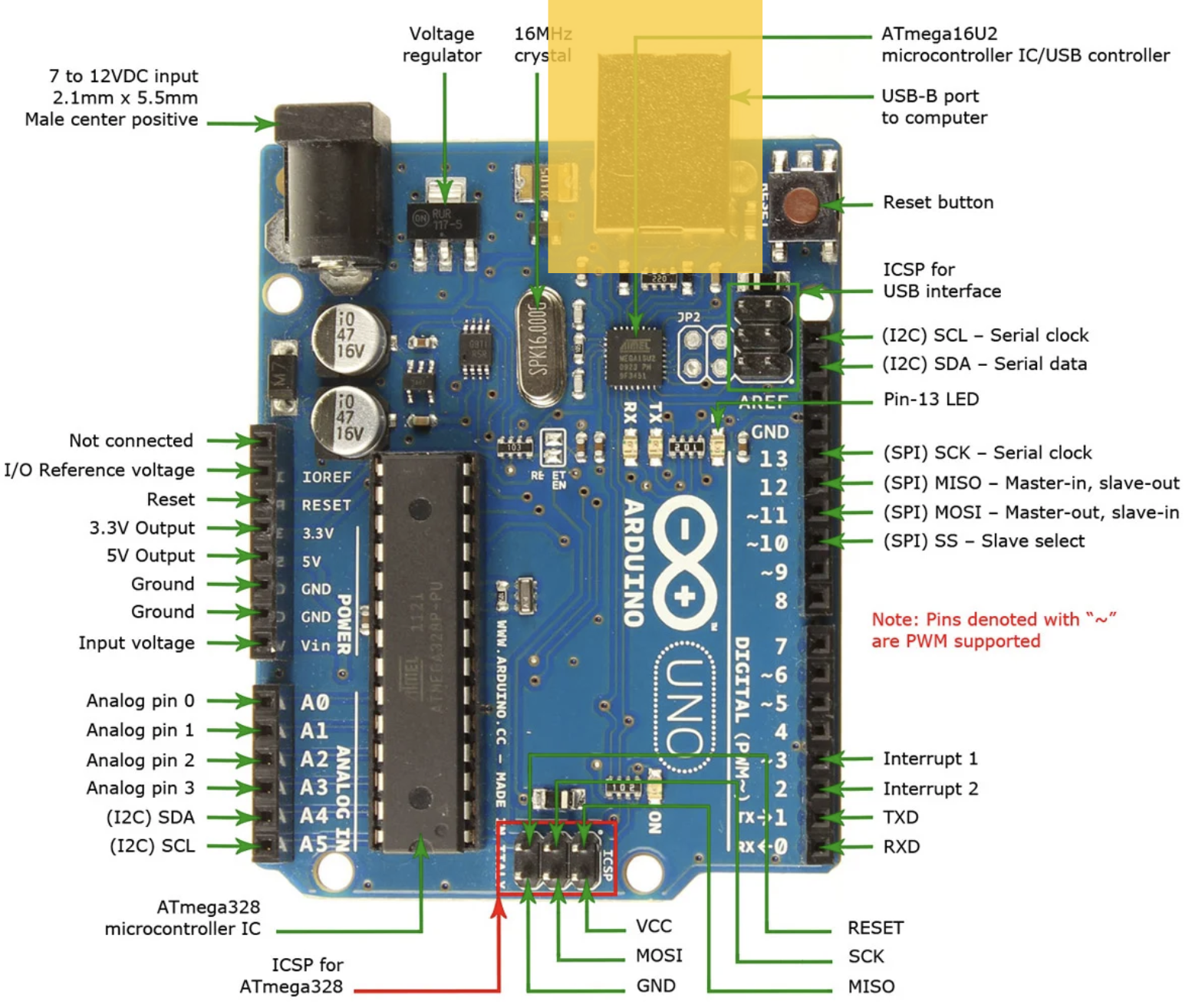

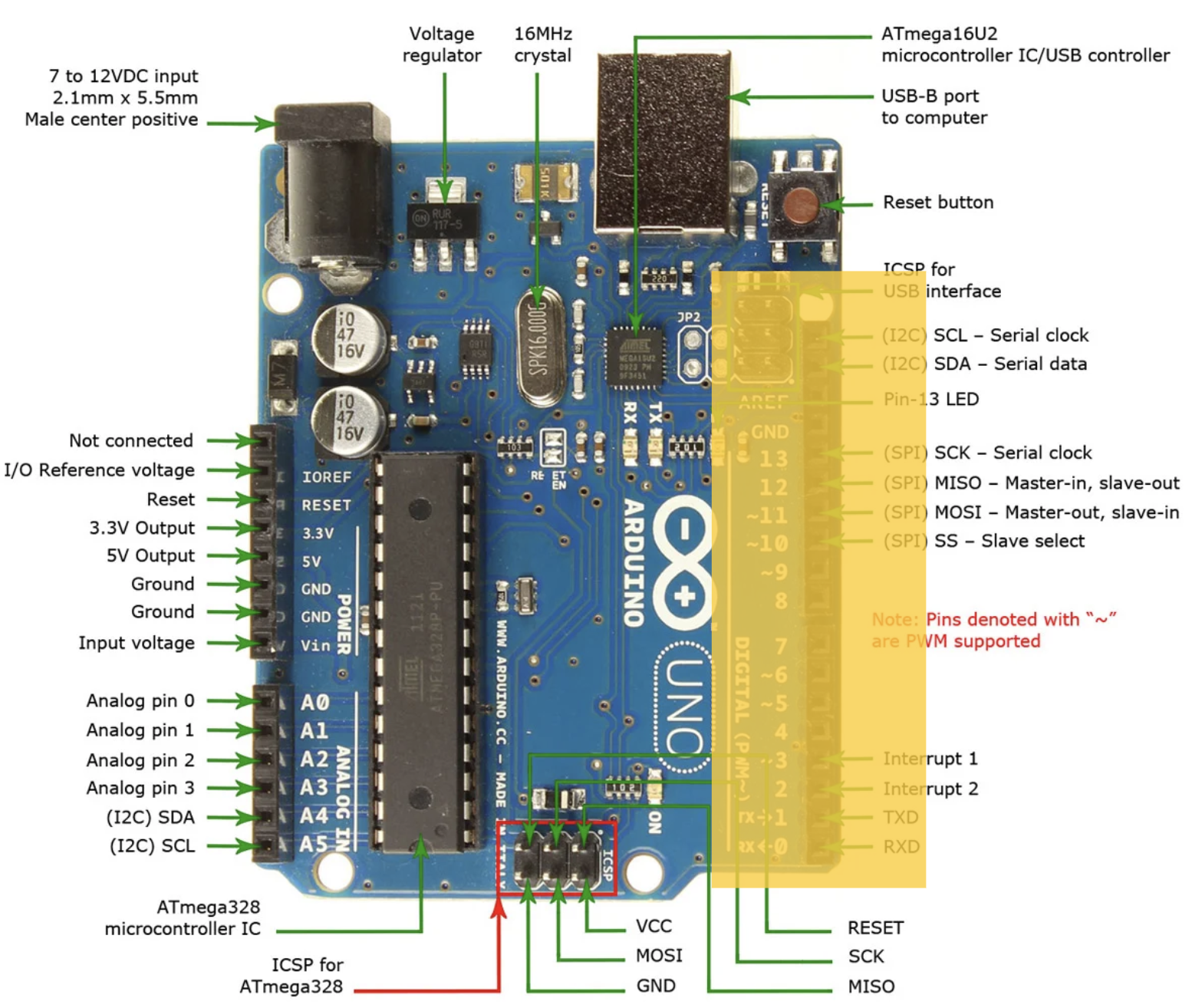

Arduino Uno Overview

USB Connection

- Used to upload code to the Arduino microcontroller

- Powers the Arduino during programming

- Enables serial communication for debugging

Digital Input/Output Pins (0-13)

- Pins can be HIGH (5V) or LOW (0V)

- Outputs: Turn on an LED every 10 seconds to make it blink

- Inputs: Read sensor data (e.g., is surface wet or dry?)

- Pins with ~ symbol: Support PWM (Pulse Width Modulation)

- PWM pins: 3, 5, 6, 9, 10, 11

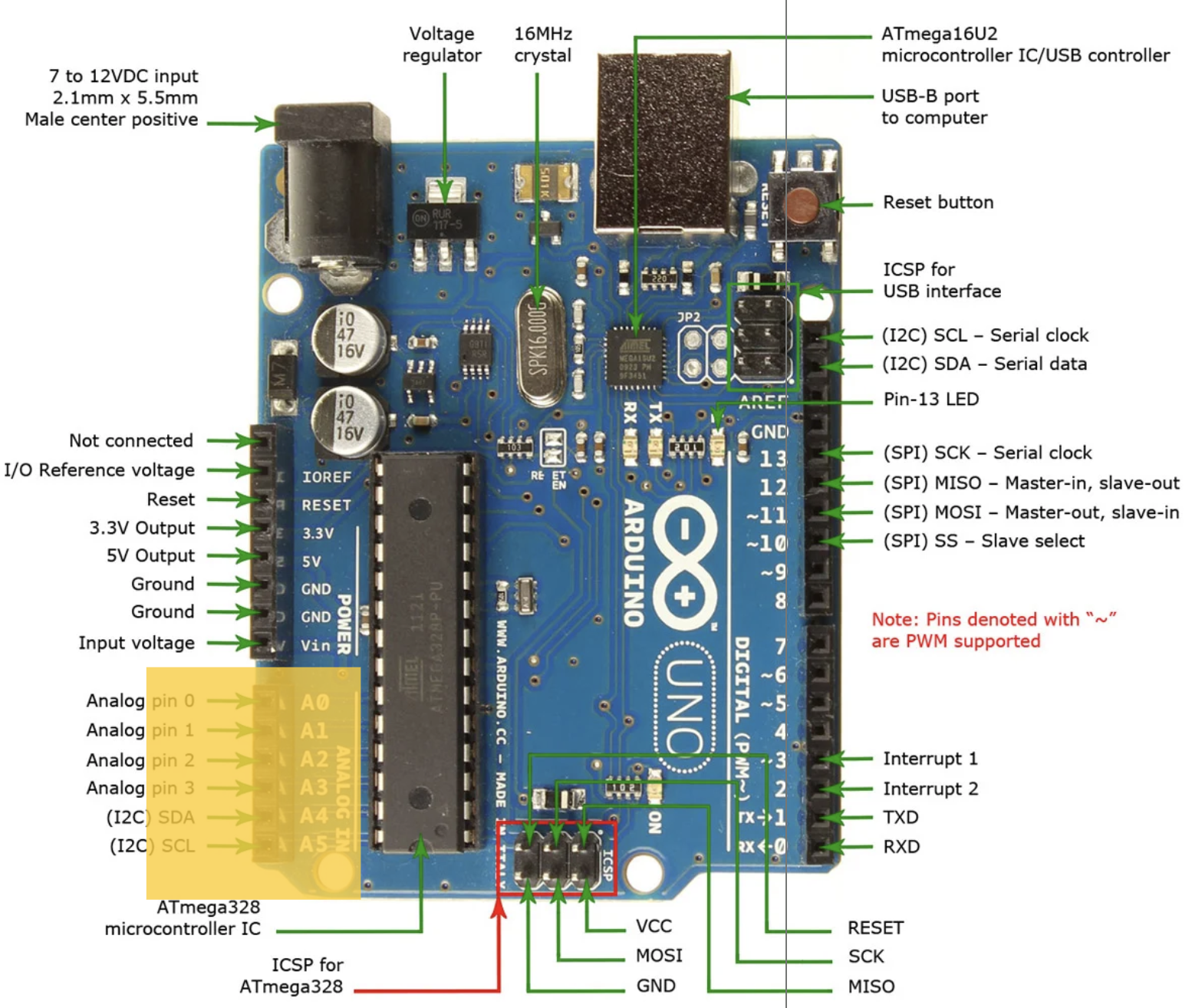

Analog Input Pins (A0-A5)

- Can read a range of values (0-1023)

- Perfect for sensors with continuous output

- Examples: Distance sensors, light sensors, temperature sensors, potentiometers

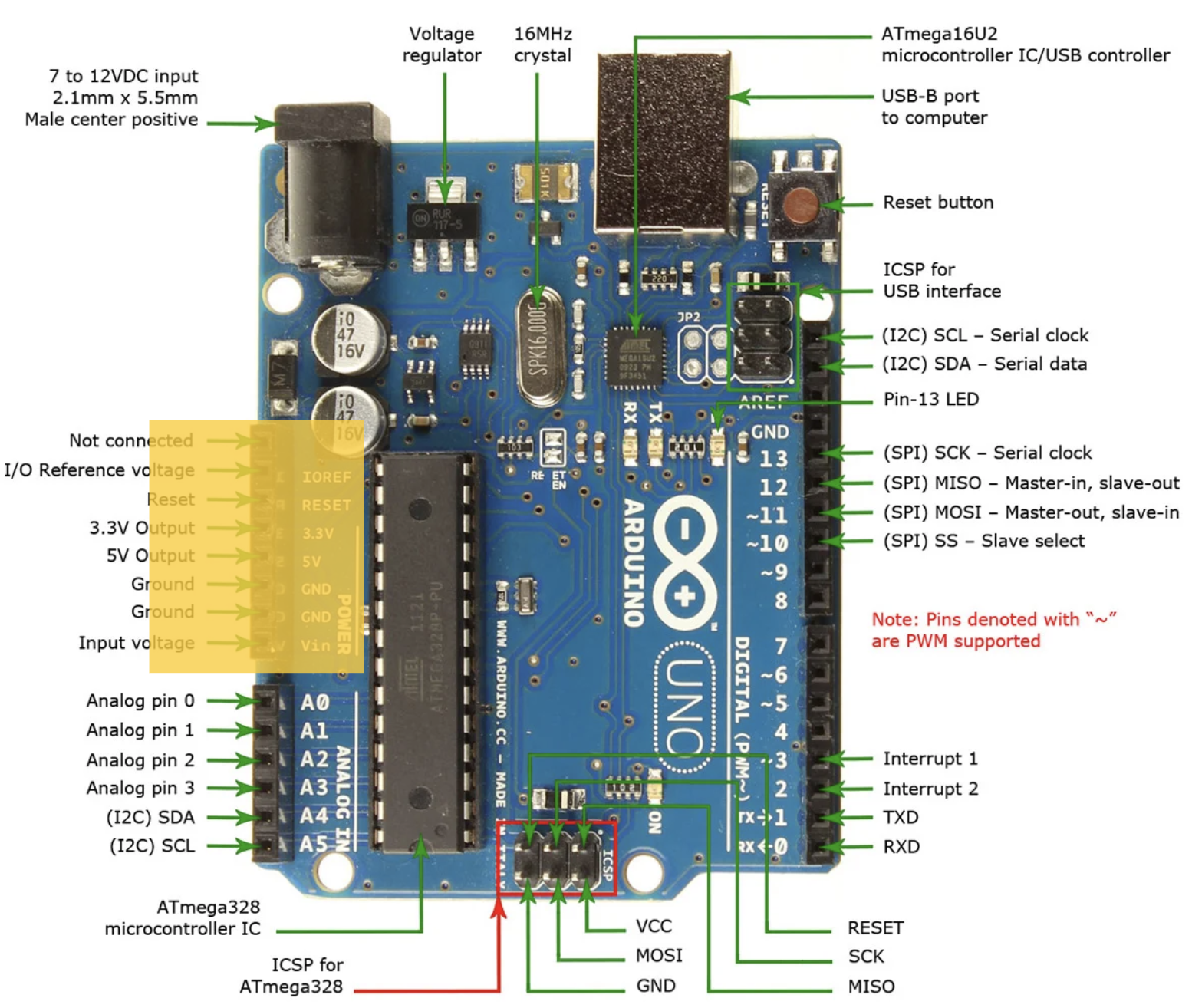

Power and Ground Connections

- 5V pin: Provides 5 volts (HIGH)

- 3.3V pin: Provides 3.3 volts (for sensitive components)

- GND pins: Ground/reference voltage (LOW, 0V)

- Vin: Input voltage (7-12V recommended)

- Circuits flow from GND to HIGH to complete the circuit

Digital vs. Analog Signals

Digital

HIGH (5V) or LOW (0V)

- ON or OFF (like light switch)

- Pins 0-13

digitalWrite(13, HIGH)

Analog

Range: 0V to 5V

- Continuous values (like dimmer)

- Reads 0-1023 (Pins A0-A5)

analogRead(A0)

Pulse Width Modulation (PWM)

Problem: Arduino digital pins are only HIGH or LOW

Question: How do we get "in-between" voltages?

Answer: PWM = rapidly switching between HIGH and LOW!

How PWM Works

Rapidly switch HIGH/LOW → Motor sees average voltage

Duty Cycle Examples:

- 25% duty cycle: 0.25 × 5V = 1.25V

- 50% duty cycle: 0.50 × 5V = 2.5V

- 75% duty cycle: 0.75 × 5V = 3.75V

- 100% duty cycle: 1.00 × 5V = 5V

PWM on Arduino

PWM pins (marked with ~): 3, 5, 6, 9, 10, 11

analogWrite(9, 0); // 0% duty cycle = 0V (motor stopped)

analogWrite(9, 64); // 25% duty cycle = 1.25V (slow)

analogWrite(9, 128); // 50% duty cycle = 2.5V (medium)

analogWrite(9, 191); // 75% duty cycle = 3.75V (fast)

analogWrite(9, 255); // 100% duty cycle = 5V (full speed)

PWM values: 0-255 (not 0-1023 like analogRead!)

Why PWM for Motors?

- ✓ Efficient: Minimal heat

- ✓ Simple: No voltage regulation

- ✓ Precise: 256 speed levels (0-255)

- ✓ Digital pins: No analog output needed

Motor inertia smooths pulses → steady voltage

Battery Voltage: 4 AA Batteries

Question: Yellow DC motor kit comes with 4 AA battery holder. What voltage is this?

Answer: 6 volts

How Do We Know?

AA battery = 1.5V (1.2V rechargeable)

Series connection: Voltages ADD

4 × 1.5V = 6V total

Series vs. Parallel Batteries

Series: Voltages ADD

- End-to-end: 1.5V + 1.5V + 1.5V + 1.5V = 6V

- Capacity: Same (2000 mAh)

Parallel: Capacity ADDS

- Side-by-side: Voltage stays 1.5V

- Capacity: 4 × 2000 = 8000 mAh

Battery Voltage Over Time

| Battery State | Alkaline AA | Your 4× AA Pack |

|---|---|---|

| Fresh | 1.5V - 1.6V | 6.0V - 6.4V |

| Nominal | 1.5V | 6.0V |

| 50% used | 1.3V | 5.2V |

| Depleted | 1.0V | 4.0V |

⚠️ Motors slow down as batteries drain!

Why We Need Motor Drivers

Critical Problem: Arduino pins cannot directly power motors!

Arduino Pin Limitations

Arduino Pin

- Max: 20-40 mA

DC Motor

- Needs: 150-300 mA

- Stall: 1-2 A

Motor draws 10× more than Arduino!

What Happens Without a Driver?

✗ Direct connection

- Pin tries to supply 150+ mA

- Rated for only 20-40 mA

- → Damaged Arduino!

✗ Motor stalls

- Current spikes to 1-2 A

- → Permanent damage!

Motor Driver to the Rescue!

Power bridge controlled by low-current signals

- Arduino: LOW current control (< 20 mA)

- Driver: HIGH current from battery (1-2 A)

- Motor powered by battery, not Arduino

- Arduino stays safe!

Motor Driver Functions

- ✓ Current amplification

- ✓ Direction control (H-bridge)

- ✓ Speed control (PWM)

- ✓ Protection (overcurrent)

- ✓ Isolation (reduces noise)

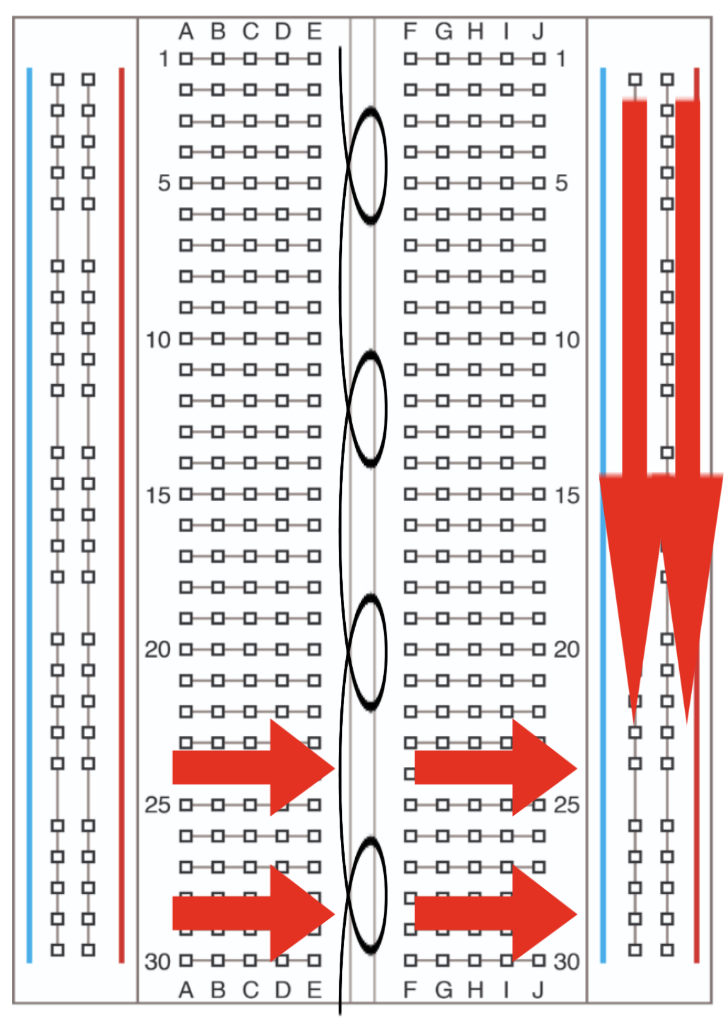

Breadboard Basics

- Solderless prototyping

- Horizontal rows: Connected

- Vertical rails: Power/GND

- Red: + voltage (5V)

- Blue/Black: Ground (GND)

DC Motors for Project 1

Yellow Geared DC Motors

- Type: Brushed DC with gears

- Voltage range: 3-6V (motor's operating range)

- Your power: 4× AA = 6V (at upper limit)

- Application: Wheeled robot

- Features:

- Gears reduce speed, increase torque

- Two-wire control (polarity = direction)

- Current: 150-300 mA (1-2A stall)

Motor Driver: L298N

- Controls: Speed & direction

- H-Bridge: Bidirectional control

- Specs:

- 2 motors, up to 2A each

- Logic: 5V, Motor: 5-35V

- Pins:

- IN1/IN2: Motor A direction

- IN3/IN4: Motor B direction

- ENA/ENB: Speed (PWM)

Alternative Motor Drivers

TB6612FNG

- More efficient

- Up to 1.2A/channel

WWZMDiB

- Compact design

- Space-saving

Any driver works for Project 1!

Next Steps for Project 1

- Mechanical build, wiring, power

- Install fresh batteries (6V)

- Test motors before mounting

- Verify driver connections

- Start with low PWM (50-100)

- Document your wiring

Types of Electric Motors

- Brushed DC Motors (what you're using)

- Brushless DC Motors

- Stepper Motors

- Servo Motors

Brushed DC Motors

Pros

- Simple control

- Inexpensive

- Widely available

Cons

- Brush wear

- Lower efficiency

- Needs maintenance

Brushless DC Motors

Pros

- Higher efficiency

- Longer lifespan

- More torque/weight

Cons

- Needs ESC

- More expensive

- Complex control

Use: Drones, RC cars

Stepper Motors

Pros

- Precise positioning

- Holds position

- No encoder needed

Cons

- Lower speed

- Can lose steps

- Needs driver

Use: 3D printers, CNC

Servo Motors

Types

- Standard: 0-180°

- Continuous: 360° speed control

- Digital: Faster, stronger

Built-in control, easy to use, compact

Use: RC vehicles, arms

Other Actuation Technologies

Hydraulic

- Pressurized liquid

- Very high force

- Large, expensive

- Use: Construction

Pneumatic

- Compressed air

- Lightweight, safe

- Lower force

- Use: Soft robotics

Safety Considerations

Active

- Torque limiting

- Collision detection

- Emergency stop

Passive

- Mechanical limits

- Compliant materials

- Fail-safe brakes

- Fuses/breakers

Key Takeaways

- Digital = ON/OFF; Analog = range; PWM = fast switching

- 4× AA = 6V (series)

- Arduino pins cannot power motors directly

- Motor drivers amplify & protect

- PWM controls speed (0-255)

- Motor types: trade-offs in precision, force, speed, cost

Questions?